User:Tim/AutomationElaboration

Contents |

Automation

< my plan is to add general summary of automation and usable current solutions for RBE >

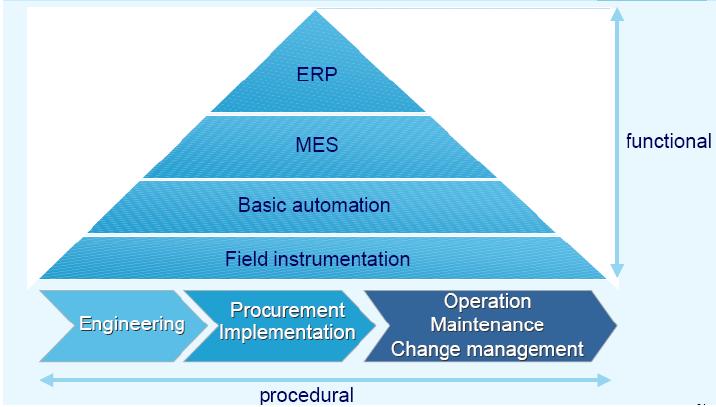

In general most production facilities can be divided in these layers.

L1: Instrumentation

This is the layer that contains the machines and the electronics dealing with the machines. In the case of industrial automation, this are the relays to switch power for machines, electric motors, valves, sensors for flows, weight, pressure, temperature, light... To connect this to the rest of the system are their the I/O modules. This modules convert the usually analog signals to digital numbers and the digital numbers to currents, voltage and pulse width modulations.

[how to build relays and electric motors not discussed here]

The open source solution often used in small scale projects is the Arduino [1]. It is a simple programmable micro controller with a few I/O pins. Some of this pins can be used as a [2] to add a lot more I/O modules. A standard way of interfacing in this way is to use [3] over ethernet.

L2: Control

In this layer is usually the classic PLC [4]. This thing monitors and controls all I/O. In automation projects it takes commands given by other systems like "add 100 liter water" and translates this into "open valve A, start pump B, wait to sensor C increases by 100, ...".

The open source solution for this is for example Proview [5]. This software changes a Linux computer to a PLC, capable of controlling I/O modules with modbus or other protocols.

L3: Supervisory

L4: MES

L5: ERP

Cite error:

<ref> tags exist, but no <references/> tag was found